Hydrogen – the gas to power the future?

Hydrogen is an increasingly important piece of the net zero emissions by 2050 puzzle. It is derived from water, and when burnt, it only emits water vapour. So, what are the pros and cons of the apparent super fuel? And why aren’t we using it already?

Why do we need it?

Hydrogen power has the potential to revolutionise the way we produce and consume energy, providing a clean, efficient, and sustainable alternative to fossil fuels. Hydrogen produces no harmful emissions and its versatility as an energy source means it can be used to power vehicles, homes, and industries without releasing pollutants or contributing to climate change.

Many industrial processes have been designed to utilise natural gas. Natural gas consists of hydrocarbons, predominantly methane (CH4). This means that carbon dioxide is released as a result of the combustion process. In burning the gas, greenhouse gases are emitted and climate change is exacerbated. Many homes also use natural gas for their boilers, ovens and hobs. In the UK, 85% of homes utilise this gas for heating and 40% of electricity is generated using gas[1].

Hydrogen is touted as a potential replacement for natural gas as it could be transported through our existing gas network and easily stored with conventional technology. This would be a more cost-effective solution, reducing the amount of expensive new infrastructure needed to build new hydrogen transmission and distribution networks, and also minimising disruption. The National Grid in the UK are running tests to see how they might utilise the current natural gas network to transport hydrogen instead.

Beyond the benefits of reduced emissions, hydrogen fuel cells have a higher energy efficiency than traditional combustion engines. Fuel cells convert the chemical energy in hydrogen directly into electricity, with no combustion or moving parts, resulting in greater efficiency as well as a lower carbon footprint.

What are the drawbacks?

While hydrogen power has many benefits, there are also some potential dangers and negative aspects to consider.

Current projects are attempting to blend natural gas and hydrogen, with the ambition to increase the concentration of hydrogen over time, thus decreasing the carbon footprint of the mixture. The good news is that plastic piping suitable for transporting hydrogen has already been deployed to much of the UK. However, whilst steps have been taken to adapt our infrastructure ahead of the proposed transition to a hydrogen/natural gas blend, parts may still need to be adapted to account for the differences between the two molecules. For example, methane is more dense than hydrogen and so the current pipelines might not be suitable in their current state to accommodate this different property.

Other challenges exist beyond adapting our infrastructure. The production of hydrogen involves the splitting of water molecules using electrolysis. An electrical current is applied to water (H2O) and this separates the oxygen atom from the two hydrogen atoms (H2). This process requires a lot of energy and the majority of hydrogen produced today uses fossil fuels (usually gas) as the fuel for this process. This attaches a carbon footprint to the production of hydrogen gas, even though there are no carbon emissions associated with its own combustion. In order to maximise the environmental benefits of hydrogen, renewable energy sources should be used in its production.

In addition, the energy required for electrolysis is costly. Currently, the cost of producing and storing hydrogen is higher than that of fossil fuels. This may limit the widespread adoption of hydrogen power until more efficient and cost-effective methods of production are developed.

Costs need to come down in order to make this economically viable. Electrolysers are expensive and this feeds through to the cost of the resultant hydrogen.

It is also important to remember that hydrogen is a highly flammable gas, and safety precautions must be taken during its production, storage, and transportation to prevent accidents. Fuel cell systems are generally safe, but there is always a risk of leakage or combustion if proper safety measures are not in place.

In summary, while hydrogen power has many benefits, it also has some challenges that must be addressed to ensure its safe and widespread use as a clean energy source.

A guide to the hydrogen colour chart

The environmental credentials of hydrogen depend on the energy used in its electrolysis. In order to distinguish between different categories of hydrogen, colours are assigned to different production methods.

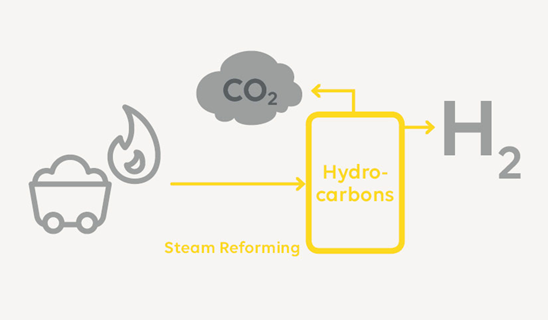

- Grey – The majority of the hydrogen production today is generated using steam methane reformation. This brings together natural gas and heated water in the form of steam. Greenhouse gases are made in the process.

Image: [2]

Image: [2]

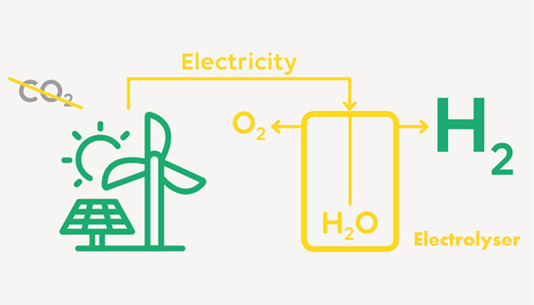

- Green – if the source of the electricity used in electrolysis is renewable then the resultant hydrogen is referred to as green hydrogen. This method of production is preferable for the energy transition but has yet to be implemented at scale. Green hydrogen would serve as an alternative fuel for many carbon intensive industries such as transport, steel manufacturing and shipping to help reach net zero.

Image: [3]

Image: [3]

The most common questions that arise from this method of hydrogen production are:

Why not use the renewable energy directly rather than using it to make green hydrogen? – The consensus is that renewable electricity should be used directly where possible but in industries like steel and cement, this is not feasible. Turning iron ore into steel currently requires coal but green hydrogen could provide an alternative. Similarly, the hydrogen could be used in some transport systems (trucks that would not work well if battery operated and some trains where electrification is not feasible). For example, JCB have developed the world’s first working construction machines powered by hydrogen. They have also developed a mobile hydrogen refueller[4].

In homes, why not use heat pumps? Centrica estimates that 6 million homes are not suitable for heat pumps. A lot of insulation and water tanks are needed, this causes a significant disruption to homeowners. Heat pumps do have a role, but they cannot be used in some properties. In these cases, it might be suitable to use a hydrogen boiler as a replacement. Most new boilers sold in the UK are able to run on a hydrogen blend ahead of a move towards hydrogen. However, boilers that are able to run on 100% hydrogen are still in development[5].

- Blue – produced mainly from natural gas, but the resultant carbon emissions are sequestered via Carbon Capture, Use and Storage (CCUS). Critics say this is not a reliable source of clean energy as it is still dependent on fossil fuels and not all of the resulting greenhouse gas emissions will be captured. In fact, some research suggests that blue hydrogen is associated with higher Greenhouse gas emissions than grey hydrogen due to “fugitive methane” that escapes during the carbon capture process. [6]

Blue hydrogen has widespread support from companies that supply natural gas. These companies have vested interest in maintaining a status quo that we should move away from. If blue hydrogen is supported by the government, the natural gas will be identified as having a role in the transition to a green economy. Understandably, this is highly contentious. In 2021, the chair of the UK’s hydrogen industry association quit his position over the issue. Upon his resignation, he made a damming statement via LinkedIn: “I believe passionately that I would be betraying future generations by remaining silent on that fact that blue hydrogen is at best an expensive distraction, and at worst a lock-in for continued fossil fuel use that guarantees we will fail to meet our decarbonisation goals.”[7]

However, proponents of blue hydrogen argue that it will act as a necessary stop gap as we move from grey hydrogen being the most prominent production methodology to green hydrogen.

Whilst the debate rages over the role of blue hydrogen in a low carbon economy, there are newer means of production that are still being trialled:

- Turquoise hydrogen – produced using a process called methane pyrolysis. This process uses high-temperature heat to break down methane gas into hydrogen and solid carbon. The solid carbon produced can be used as a valuable material in industries such as construction and manufacturing.

- Yellow hydrogen – produced using nuclear energy to split water molecules into hydrogen and oxygen. This process is not yet commercially viable but is being researched as a potential future source of clean hydrogen.

Regulatory priority

Governments and supranational organisations are placing a growing emphasis on the role hydrogen will play in national net zero targets.

The Inflation Reduction Act in the US has prioritised clean hydrogen as a fuel of the future and has set a goal to reduce the cost to $1/kg by 2030. The current cost is roughly $5 per kilogram[8]. This ‘clean’ hydrogen refers to both green and blue hydrogen.

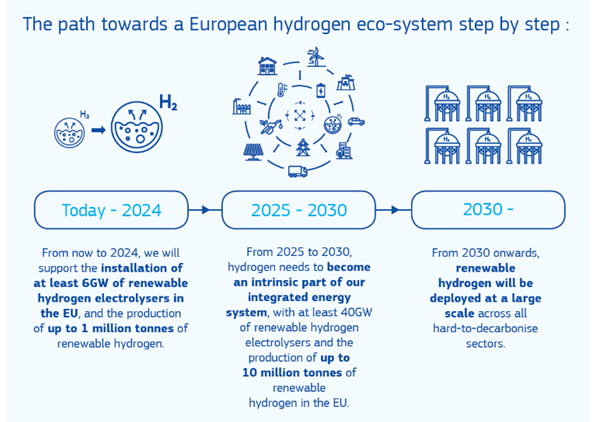

The European Union have also created a ‘Hydrogen Strategy’. This was adopted in 2020 and is designed to create a hydrogen ecosystem in Europe. The ambition is to produce 10 million tonnes and import 10 million tonnes of renewable hydrogen in the EU by 2030. The focus of these actions is to accelerate the uptake of green hydrogen in energy-intensive industrial processes.

Image: [9]

Image: [9]

The UK net zero plans are also backing the further adoption of hydrogen. The UK hydrogen strategy not only focuses on green hydrogen, but also backs the further adoption of CCUS to be used in conjunction with the production of hydrogen from methane gas. The government have set an ambition for 5GW of low carbon hydrogen production capacity by 2030[10].

Some companies are already investing in technology to increase the capacity of the UK to produce and deploy hydrogen at scale. Alongside infrastructure trials being undertaken by the national grid, a UK company has succeeded in creating the world’s largest electrolyser production facility. ITM Power moved to its new Gigafactory in Sheffield in 2021. ITM Power designs and manufactures electrolysers based on proton exchange membrane (PEM) technology to produce green hydrogen, using renewable electricity and water[11]. This emphasises another benefit of hydrogen, domestic production will serve to reduce dependence on foreign oil and gas to increase energy security.

Our view

There are different needs within the energy system. Some can be met with renewable electricity, battery operated vehicles and heat pumps. However, for those operations that are more difficult to decarbonise with these solutions, hydrogen could be the answer.

With regard to the rainbow of colours associated with hydrogen, it seems clear that the scale up of green hydrogen production should be the priority. Whilst blue hydrogen does provide a better alternative to the most common grey hydrogen at present, this ‘low’ carbon solution is still not as good as the zero-carbon alternative of green hydrogen.